How to Deal with Stuck Joints in Sex Dolls: Professional Repair and Maintenance Guide

Sometimes, even your sex doll needs a bit of "joint care"! When you're ready to enjoy quality time with her, but notice her pose is as stiff as a beginner in yoga, don’t worry—it’s not a "joint crisis." Whether your doll is made of TPE or silicone, her joints might become less "cooperative" over time (just like humans), but this issue can easily be solved with some simple maintenance. Here, we provide a step-by-step guide to help restore her "flexibility," making every interaction smoother and more enjoyable!

1. Understanding the Skeletal Structure of Sex Dolls

2. Common causes of joint entrapment

3. Step-by-step guide to dealing with jammed joints

4. Frequently asked questions

-------------------------------------------------------------------------------------------------------------------

1. Understanding the Skeleton Structure of Sex Dolls

When handling joint issues in sex dolls, understanding their skeleton structure is key. Modern sex dolls usually feature stainless steel or aluminum alloy skeletons, with ball joints or hinge joints that simulate natural human movements.

-

Ball Joints: Similar to human shoulders and hips, these joints allow for free rotation in multiple dimensions, providing a wide range of motion. Ball joints connect through a spherical joint and socket, allowing for three-dimensional rotation.

-

Hinge Joints: Like human elbows and knees, hinge joints allow for single-direction bending and extending. These joints are typically secured with bolts, limiting lateral movement and ensuring stable, natural motion.

The joint areas are fixed using bolts and metal brackets. Bolts provide flexibility for adjusting joint tension, and high-end dolls often include low-friction padding materials like nylon or PTFE (Teflon) to reduce joint friction and extend lifespan.

2. Common Causes of Stuck Joints

Regardless of whether your doll is made from TPE or silicone, joint stiffness often occurs due to:

- Long Periods of Inactivity: Keeping the doll in the same position for extended periods may cause joint stiffness, especially in less frequently used areas.

- Lack of Lubrication: Without proper lubrication, metal components may rub together, making movement difficult.

- Environmental Factors: Changes in humidity or temperature may cause metal components to rust or age, affecting joint flexibility.

- Excessive Force: Improper positioning or using too much force can damage or deform the joints.

- Manufacturing Tightness: New dolls tend to have tighter joints due to the material's firmness and manufacturing processes, requiring some use before becoming more flexible.

3. Step-by-Step Guide to Fix Stuck Joints

Step 1: Assess the Problem

- Identify the stuck joint: Gently try to move each joint to find which one is restricted. Pay attention to any noises or resistance.

- Check for external damage: Inspect the doll's exterior, especially around the joints, for cracks, damage, or abnormalities on the skin surface.

Step 2: Preliminary Treatment

- Gently move the joint: Hold the joint on both sides and apply gentle, even pressure to gradually move the joint. Avoid pulling or yanking.

- Heat treatment: Use a hair dryer on a low-heat setting to gently warm the stuck joint for a few minutes. This can soften the TPE or silicone material, making the joint more flexible.

Step 3: Lubricate the Joint

- Choose the right lubricant: Select a suitable lubricant based on the doll’s material. For TPE or silicone dolls, use dedicated care oils and avoid silicone-based products, as they can damage the materials.

- Lubrication steps: Apply a moderate amount of lubricant to the joint area and gently massage it in to help the oil penetrate. If possible, use a syringe to inject lubricant directly into the joint connection to ensure thorough lubrication.

Step 4: Move the Joint Again

- Repeat the movement: After lubrication, gently move the joint again, gradually increasing the range of motion.

- Observe the feedback: If the joint becomes more flexible, continue moving it several times until it feels normal.

Step 5: Deeper Repair (If Necessary)

If the above steps do not resolve the issue, deeper repair might be required.

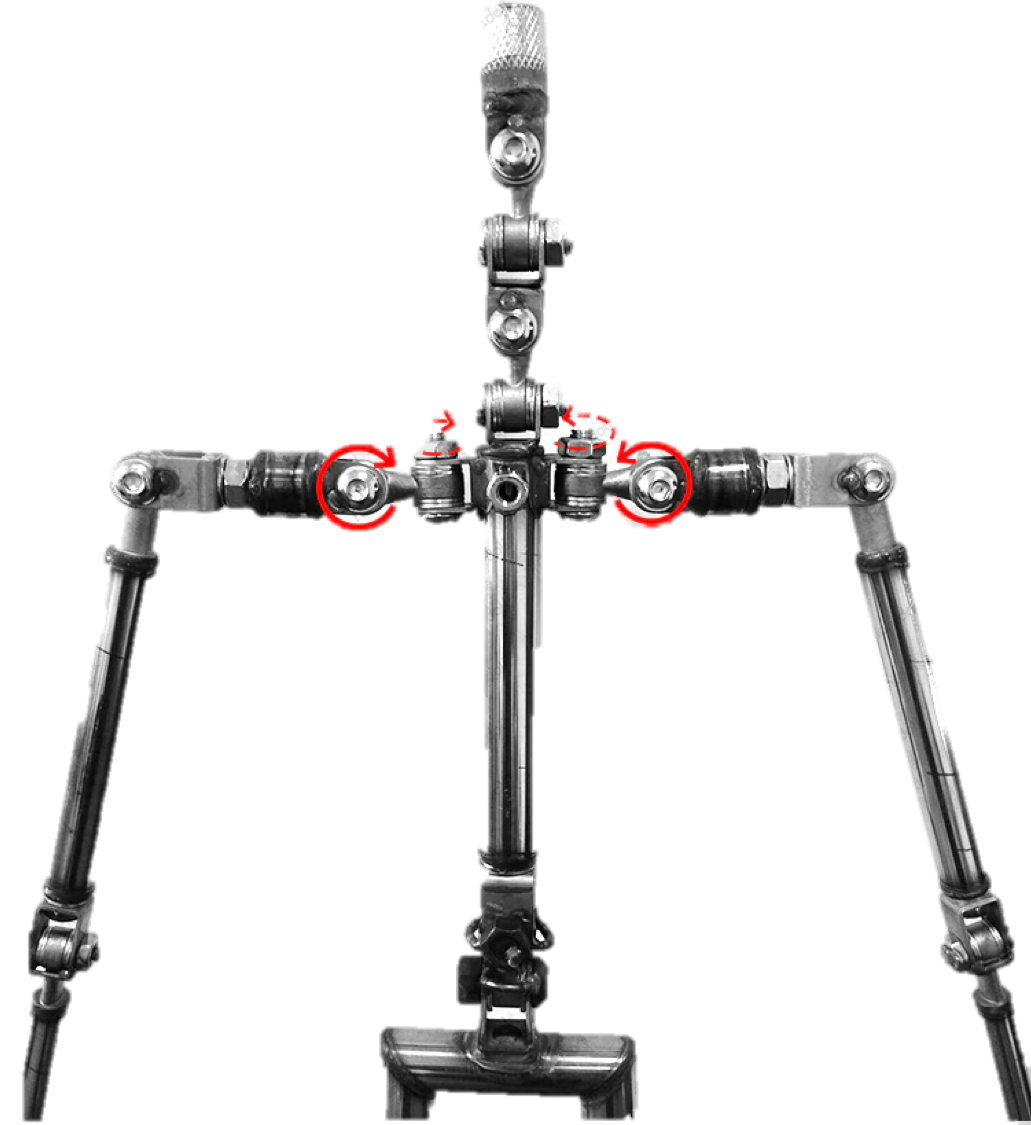

- Disassemble the joint: Use a sharp tool to carefully cut along the joint seam, exposing the internal skeleton. For TPE and silicone dolls, ensure precise cutting to avoid damaging other areas. Always wear protective gloves to prevent injury.

- Inspect the skeleton: Check the joint bolts and hinges for looseness, rust, or damage. Use the appropriate tools (e.g., a wrench) to tighten loose bolts and restore joint functionality.

- Replace parts (if necessary): If the joint is damaged, contact the manufacturer for original replacement parts. Once you have the new parts, reinstall them according to the doll’s original structure, ensuring proper joint operation.

- Repair TPE or silicone skin: To fix the skin, use specialized TPE or silicone glue to seal the incision. Alternatively, use a hairdryer or heat gun on low heat to help the material fuse. Once dry, gently sand the seam to restore the skin’s smooth, natural appearance.

4. FAQs

How often should I check the joints?

It’s recommended to check your doll’s joints every 3 to 6 months, especially if you frequently use or change her poses.

What type of lubricant is best?

To avoid damaging TPE or silicone, use silicone-based lubricants or mild oils like baby oil.

What if the joint is still stuck after following these steps?

If your doll’s joint remains tight, contact the manufacturer for guidance or seek professional doll maintenance services.

Conclusion

Whether your sex doll is made of TPE or silicone, joint stiffness is a common maintenance issue. By following this guide, you can effectively resolve the problem. With proper care and maintenance, you can extend your doll’s lifespan, keep her flexible, and ensure long-term satisfaction.

Leave a comment

Please note, comments need to be approved before they are published.